The following article focuses on Millville paperweight-making in the 20th century, especially the owner’s struggles with the rose design. It also details other popular designs that Millville artists created, such as fire-devil and lily, and explains how paperweights are made. It originally appeared in the December 1938 issue of American Collector magazine (Volume VII Number 11), a publication which ran from 1933-1948 and served antique collectors and dealers.

Victor Durand, owner and operator of this Vineland plant, never owned a factory in Millville. He started in Vineland in 1895 with a tube shop, where he made electric bulbs and later X-ray tubes. By 1920, he had one of the finest art glass plants of its type in the country. Being greatly interested in the art glass department, Ralph Barber attempted paperweights while there and made several of the lily design.

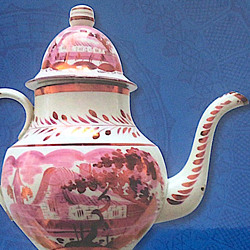

A Typical Rose from Millville: The paperweight, complete with the circular base or foot, is representative of the way the work was finished with those examples that were sold.

In 1918, he tried again to make roses, but with no success. This was not because he was any less of a craftsman, but because Durand didn’t have the setup of the Whitall Tatum wooden mold department. The proper colored cullet was not available; instead of ovens there were only annealing lehrs, which tempered glass in much less time than that required for paperweights. With those he attempted, the color was off, the shape poor, and when put into the lehrs they literally exploded with the heat.

After three or four attempts, Barber gave up in disgust and Mrs. Durand, who was always active in the company’s affairs, says that he stopped making all other paperweights at that time. This experimenting at the Vineland shop was done in his spare time, on his own initiative, and without the knowledge or cooperation of Mr. Durand or anyone else there. Further, there was no visible effort by anyone else, either then or later, at making a rose paperweight at the Durarid plant.

Although overshadowed by Barber, the work of the other men who are known to have made the upright rose paperweights was not less beautiful nor less skilled. Michael Kane, who came from Germany, made them. He also is the only man definitely known to have made consistently the upright sailboat, dog flushing a covey of quail (very rare), horse, and eagle paperweights. Others tried, but without real success.

Molds for Ship Paperweights: That inscripted "Rocked in the Cradle of the Deep," is for a flat type; that depicting a ship akin to an Egyptian dhowda, for a vertical paperweight.

The colors used in the rose paperweights were ruby, pink, opal, and opalescent yellow. These pieces were made with and without a foot; with or without leaves; and in combination of each. Some were made on a foot; on a foot and a column; on knopped stems with a foot and a bud; sometimes tilted; sometimes at right angles to the perpendicular; and also as inkstands with a rose in the stopper.

The white or opal rose was the result of trying out a new crimp. It was a regular color used by the factory and was therefore more practical for experiment than the more expensive ruby. This is why the white rose is often found minus both foot and leaves, the men not troubling to complete a trial paperweight.

Emil Stanger is the only maker of rose paperweights who is known to have produced, at times, his own leaves. Those of the other men were lamp room work. Alex Querns, a skilled worker and boss of the lamp room at Whitall Tatum & Company, was their main and probably sole source of supply. None of the men made the colored canes used in the millefiori paperweights. They were bought elsewhere in long bars and broken or cut as used. This is not surprising, for the making of these canes was too complicated to be attempted in anyone’s spare time.

Two Millville Lily Paperweights: The footed example at the left, probably made by Marcus Kuntz, has a flower of turquoise blue with opal background. That at the right by John Rhulander is a lily formed of white glass with the stem very distinct, extending upward from the foot.

Other designs produced by these men were the lily (never called a mushroom), the fountain, devil’s fire, and some half-round paperweights with scene and inscriptions on the bottom, such as “Old Faithful,” “Life on the Ocean Wave,” and the like. There was a calla lily of opalescent yellow with a stamen, but no leaves. This, like the rose, was made with a crimp. I was also told of a daisy design, but could not find out anything about it, other than that it was made.

The initial steps in making the Millville lily were the same as with the rose. As the mass of molten clear glass took on the required shape, opal glass was placed on the flat end, the whole heated to the proper plasticity and placed opal down upon an assortment of colored broken glass. Then it was heated again. Sometimes this operation had to be repeated to gather more colored glass onto the opal.

After this the lily crimp was pressed into the colored glass and opal, forcing it into the clear glass, and the crimp removed. A long tool, similar to an ice pick, but generally the handle of one of the regular glassmaking tools, was forced far enough into the glass to form the stem of the lily and withdrawn.

A “knife” or hook was next placed in each indentation made by the crimp and pulled around the sides of the paperweight until the desired shape was reached. More flint glass was then laid over the entire surface, the air entrapped in the stem expanding and rising to form the ever-present bubbles in this type of paperweight. The top was blocked to shape and the pontil cracked off. Then the foot was made and applied as in the rose weight and the pontil put on the bottom again. More clear glass was gathered over the entire weight, re-blocked and pontil cracked off the foot.

Three Paperweights of Unusual Design: That at the left shows a vertical design of a dog flushing quail. It is rare and was made by Michael Kane at Millville. In the center is a blue bird. It was made at the Port Elizabeth works that was demolished before the Millville wooden mold department was started. At the right an unusual "Friendship" paperweight with floating wreath, made at Millville.

If there is no evidence of a pontil on the top of these paperweights, it shows that a second gathering was made, but if the pontil mark is obvious, it is conclusive evidence that enough glass was gathered at the time of the formation of the air bubble.

For the inkwell type of lily, a bit of glass was worked into shape, using only the pincers and pontil until the well was formed on the outside, but not finished on the top or lip. It was then placed on the top of the weight and the pontil removed from the well. The latter was then blown into its final shape by inserting the pointed end of a steel blowpipe into the top with opposite end fastened to a rubber ball, forming a crude atomizer. The inside of the well being expanded, the blowing tool was removed and the neck and lip of the well finished by the dexterous use of the pincers. The stopper was made exactly like the weight, except that the neck was formed by hand.

The rose inkwell was made the same way. With the inkwells illustrated, those made by Marcus Kuntz and cut by Mr. Clunn, the wells were fashioned by the skillful handling of the pincers and the continued gathering of more and more glass to reach gradually above the hole or well. The design of these was the forerunner of the pattern for the devil’s fire paperweight.

With the upright sailboat, horse, dog, and eagle paperweights, a circular steel plate of the desired pattern was first cut in the machine shop. It was placed face up and the various colors of powdered glass placed in the lines of the pattern. The correct amount of clear glass was then gathered on the pontil and worked until it resembled a closed fist.

It was then placed on the edge of the pattern and slowly and painstakingly pushed or rolled with a tool across the face of the plate until the entire surface was covered. Only a thin layer of glass was used at first. A real technique was involved here. Not only must the design be kept thin and straight, but it was essential that no air bubbles be allowed to form between the plate and this first thin layer of glass. Their expansion with the intense heat of the molten metal would spoil the work.

The next step was to withdraw the glass from the plate. The entire mass was then covered with more clear glass and worked until round. If a foot was desired, it was then applied.

In the so-called flat paperweights, clear glass was placed over a plate of colored design. Then the plate was withdrawn, leaving the colored glass adhering to the clear. A piece of colored glass for the background was then attached to the bottom, the pontil cracked off the top, the paperweight shaped and the bottom pontil cracked off.

Such a rare type of paperweight shows a hunter in a field shooting at wild fowl, with a dog pointing. A fallen log lies in the foreground. The subjects are in color, but no colored plate has been used for the background. Considerable glass was gathered to cover the design, and when finished the paperweight was cut and faceted. From technique and comparison, I would feel justified in attributing this example to Michael Kane, and the cutting and faceting to Clunn.

Paperweight Tools: Left to Right these are: a blow-pipe and gathering iron; a wooden pallet for farming various sizes of feet for paperweights; a glassworker's pincers that had many uses, such as finishing a foot, and shaping the well of an inkstand; shears used to cut bits of molten glass; a block used to give paperweights their spherical shape; and a pontil rod, on which a paperweight was held while being made.

Occasionally, a collector will meet up with a small, Millville type of paperweight that looks something like a broken off and polished stopper. We have had these in our own collection, and on inquiring about them were reliably advised that they were really experimental paperweights, and not stoppers. They were of the fire-devil and lily type. Being the same size as the inkwell stoppers has undoubtedly lent credence to the legend mentioned.

Referring again to the lily paperweights, I might add that John Rhulander was the only worker known to have drawn down the petals with a hook, which of course makes his work not only quite outstanding but easy to attribute as well.

There is no more fascinating type of paperweight to collect than those made at Millville and vicinity. These workers, skilled in their own department of glass working, were true artists at heart, and with the encouragement of their employers and the free use of expensive materials and equipment, created these objects so coveted today.

Many rumors are afloat regarding reproductions of them, particularly of the roses. It has been reported that they are identical with the old ones in every respect, but I have not yet seen a reproduction that could be even remotely confused with an original.

NOTE: For help in my research and in authenticating the data set forth in this article, I wish to acknowledge the indefatigable efforts of Edward Griner. Also to Whitall Tatum Company, William F. Breeden, Mr. Saunders, members of the Barber and Rhulander families, and S. Edna Fletcher, my sincere thanks are due.

This article originally appeared in American Collector magazine, a publication which ran from 1933-1948 and served antique collectors and dealers.

Almost Famous: The Untold Story of an Artist's Rock-Poster Roots

Almost Famous: The Untold Story of an Artist's Rock-Poster Roots The Dead Files: Rock Art, Artifacts, and Psychedelic Office Supplies Up for Grabs

The Dead Files: Rock Art, Artifacts, and Psychedelic Office Supplies Up for Grabs Treasures of the Incomparable Pforzheim Jewelry Museum

Treasures of the Incomparable Pforzheim Jewelry Museum The Hippie Daredevils Who Were Just Crazy Enough to Invent Mountain Biking

The Hippie Daredevils Who Were Just Crazy Enough to Invent Mountain Biking Beautiful But Deadly: The Creepiest Devices From Medicine's Grisly, Leech-Filled Past

Beautiful But Deadly: The Creepiest Devices From Medicine's Grisly, Leech-Filled Past Art Glass PaperweightsSome of the earliest paperweights were made in Venice in the 1840s. They we…

Art Glass PaperweightsSome of the earliest paperweights were made in Venice in the 1840s. They we… Mari Tepper: Laying it on the Line

Mari Tepper: Laying it on the Line Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry

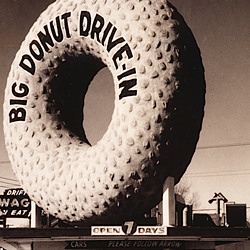

Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry How Jim Heimann Got Crazy for California Architecture

How Jim Heimann Got Crazy for California Architecture Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of

Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick?

Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick? When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll

When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll How One Artist Makes New Art From Old Coloring Books and Found Photos

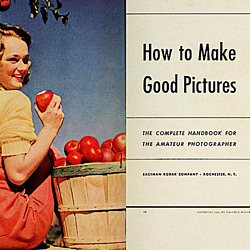

How One Artist Makes New Art From Old Coloring Books and Found Photos Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures

Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History

Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Correction on Michael Kane, he born in Ireland, not Germany. He was my great grandfather.

Is there anyone who appraises paperweights in or around the Millville Glass Company? My father-in-law had a paperweight collection including a Millville rose paperweight. Any help would be appreciated.

My grandfather who I call Poppop was taught by Barber and made beautiful things that were only seen by who they were made for. And he did the roses as well but other things that most say couldn’t be done material wise. His name is Robert Grablow. Sorry for coming off defensive but as stated quality and the way there not made as well etc… well just angered me a bit but thank you and enjoyed the article. And I also realize that you can not find ever detail when doing a piece. My apologies and you could view some of his work if you type his name. Maybe buy one of his roses on eBay but may cost a little but worth it.

To Robert Goslin, i had the privilege of working with and knowing your grandfather at Wheaton Glass, i also am lucky to have one of his Millville Roses. Its one of favorites in my Rose collection