Today’s guest blogger is hand-fan collector Anna Checcoli, whose Ventagli.org is a member of our Hall of Fame.

Many fan collectors have asked me how artists dyed mother-of-pearl fans. A collaborative article published on the FANA Forum in June, 2007, whose authors included Pierre-Henri Biger, Céline Louvet of the Mother-of-Pearl Museum near Paris, and Chuck Erikson, explained most of the techniques, which I summarize today. Other sources are cited below.

Mother-of-pearl coloring techniques are still quite mysterious because the holders of this know-how considered their techniques to be professional secrets. In general, though, we know that dyeing was practiced after shaping an object but before engraving, ornamentation, and polishing. Some processes required a double boiler, others techniques were performed cold in large stoneware jars. The mother-of-pearl would steep in pigments or corrosive products such as ammonia—the length of time depended on the desired colors. For clear colors, it was necessary to bleach the mother-of-pearl first with diluted hydrogen peroxide, as if you were coloring hair.

One of the most successful mother-of-pearls was, and is, “nacre d’ Orient,” also called “Goldfish.” In Spire Blondel’s 1875 “Histoire des Eventails,” we read of a certain Mr. Meyer, who patented a process to dye fans of this material. Meyer had a way of cutting into the surface of a shell to make it iridescent without altering its natural colors.

Other methods of coloring nacreous shell include silvering, in which silver leaf and gum water was mixed, ground, and then applied to the insides of shells. Gold colors could be achieved by substituting gold leaf in the same basic recipe, or gold powder could be produced by mixing gold leaf and gum water with honey before grinding and drying. B. Frank Van Cleve’s 1874 “The English and American Mechanic” describes mixing the resulting powder with gum water or isinglass and then applying it by wrapping a soft piece of leather around the finger, dipping it into the powder, and rubbing the shell.

According to “The Techno-Chemical Receipt Book” written in 1886, mother-of-pearl could also be dyed with aniline colors—if the dye was intended to penetrate deep into the shell, the pieces needed to remain in the coloring matter for two weeks. William B. Dick’s “Encyclopedia of Practical Receipts and Processes” from 1903 offers advice on working with lac dyes: boil the dye, allow it to settle, then dissolve in a solution of chloride of tin before dipping the shells in the preparation until they are of the desired color.

Finally, to achieve iridescence, the “Scientific American Cyclopedia of Formulas” from 1910 offer a process said to be the same one followed by Viennese button makers. Fill a wide-mouth jar with ammonia water and add powdered silver chloride until the liquid becomes saturated and a slight excess of the silver salt is established. Put the shells in the jar, cover it with a glass stopper, and set it aside in a dark place for a few days. The play of colors is usually established in a few hours, but its permanency is assured by one week’s contact with the ammonia water followed by two days’ exposure to direct sunlight.

Be a Bombshell at the Beach, Go Vintage

Be a Bombshell at the Beach, Go Vintage Why the 'Native' Fashion Trend Is Pissing Off Real Native Americans

Why the 'Native' Fashion Trend Is Pissing Off Real Native Americans A Shock of Schiaparelli: The Surreal Provocateur Who Forever Altered Fashion

A Shock of Schiaparelli: The Surreal Provocateur Who Forever Altered Fashion Hand FansBack in 1325 B.C.E., when King Tut ruled Egypt, minions would keep the air …

Hand FansBack in 1325 B.C.E., when King Tut ruled Egypt, minions would keep the air … Mari Tepper: Laying it on the Line

Mari Tepper: Laying it on the Line Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry

Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry How Jim Heimann Got Crazy for California Architecture

How Jim Heimann Got Crazy for California Architecture Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of

Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick?

Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick? When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll

When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll How One Artist Makes New Art From Old Coloring Books and Found Photos

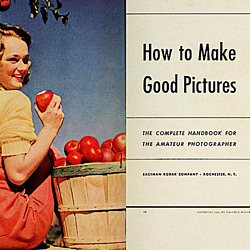

How One Artist Makes New Art From Old Coloring Books and Found Photos Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures

Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History

Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Regarding Blondel’s reference to Myer. This introduces (at least) two open and hotly debated questions: what is Meyers’ process, and what is “goldfish”? The entire paragraph in Blondel is almost identical to an entry presented in the Dictionnaire Encyclopédique et Biographique de l’Industrie et des Arts Industriels, edited by Eugène-Oscar Lami, published by Librairie des Dictionnaires, 1886 (only 11 years after the publication of Blondel), p.734, the original from Harvard University where it was digitized on Feb. 29, 2008:

“Fan-makers also employ delicately shaded white mother-of-pearl with a handsome silvery effect and coming from the amers des coquilles; but none of these pearly shells merits greater popularity than the oriental mother-of-pearl called goldfish, which over the last twenty years or so has caused a revolution in luxury fan-making. Using a process resulting from the use of aniline dyes, of which Mr. Meyer is the inventor, it has been possible to impart all the shades of the rainbow to this remarkable product. – s.B.”

Thus we can understand (without violating the grammatical sentence construction of Blondel’s text) that the “process invented by Mr. Meyer” is in reference not to “goldfish” per se as a certain type of shell, or as a particular variety of backing veneer, or even as a novel technique for working shell, but is instead addressing a then-new method of using aniline dyes to brilliantly stain various species of shell (most commonly including Japanese Awabi abalone/goldfish, as we know from existing items, but also ocean pearl oyster, Green sea snail/burgau, and even some of the other abalone species, in both their solid and veneer forms as both fan sticks and backings). In other words, Blondel is talking about Meyers’ dyeing process as being applied to an already particularly popular shell, by way of illustration, known as goldfish; but “goldfish” refers very specifically not to Meyers’ actual process but to material taken from the Japanese Awabi abalone, Haliotis gigantea, which is characterized by a distinctive “washboard” or “fiddle back” rippled figure that is unmistakable and thus easily identifiable, and is by far the shell most often seen dyed when used in fans, whether in the sticks or as backing veneers.

In being attributed to “s.B.”, the above comments from Lami’s dictionary are undoubtedly based on material from Spire Blondel, but the additional brief information about dyes could have easily been transferred from a common source they were both using, and then combined with Blondel’s statement in order to compose a more complete dictionary entry. Note that the phrase “the last twenty years or so” has similarly been added by Lami, and although undoubtedly accurate and not in conflict with Blondel, it’s also not present in Blondel’s text. It’s well known that Blondel has been misquoted in other books both old and new (as in History of the Fan, by G. Woolliscroft Rhead, 1910). Quoting or interpreting Blondel badly is one thing; but because Lami provides completely new and specific information about Meyers’ process having to do with using aniline dyes to stain shell it strongly indicates a common source of information, access to unedited or expanded versions of Blondel, or at least (and most likely) a common knowledge within the industry at that time that it was a dyeing process which Meyer had invented.

If the Lami contribution is legitimate, it helps to clear up more than one old issue among fan researchers about what exactly Mr. Meyer’s process may have applied to, since several competing ideas have been offered:

1. That Meyer had introduced a new species of shell called goldfish. This argument can be easily dismissed because whatever goldfish might be, it was obviously being used widely before Meyer came along (for “a few years” according to Blondel, and “over the last twenty years or so” according to Lami 11 years later).

2. That once Meyer had found a way to dye the thin shell veneer backing found behind some pierced fan sticks, it is these dyed shell veneers which are being specifically labeled as goldfish. As in point 1, goldfish already existed; and both Blondel and Lami clearly state that “all the shades of the rainbow” are imparted “to this remarkable product”. The “remarkable product” is not the dyeing process itself, but the well-known goldfish shell which had for some years prior “caused a revolution in the luxury fan industry” and “to” which Meyers’ process was sometimes now being applied.

It should also be noted that neither man mentions shell backing veneer as such; their only reference is to “goldfish”. Most modern readers falsely assume that “goldfish” refers exclusively in some way to these veneers and so automatically read that meaning into the text. But as shown in End Note 3 under this section, goldfish actually denotes a particular species of abalone, Haliotis gigantea, which was used immensely more as a stick material than as a backing veneer. Its ubiquitous use as a major stick material was what “caused a revolution in luxury fan-making”, not its occasional use as a veneer behind a few of the most elaborately carved of those sticks!

3. That Meyer had developed a novel method of cutting shell which gives it more iridescence, a material which was then labeled as goldfish. The enhanced coloration was accomplished using aniline dyes. Working nacreous shell is still a major industry around the world (including the editor’s professional business as The Duke of Pearl, which involves the precision cutting of hundreds of metric tons of shell annually from 18 nacreous shell species), and it can be stated unequivocally that there is not and never has been any secret method of cutting shell which increases its colors or iridescence.

Thus, “goldfish” is not what Meyer invented, only a dyeing process being used on already existing goldfish shell, which is simply another name for Japanese Awabi abalone, also known as “nacre d’Orient.

The above comments are from as yet unpublished footnotes to my translation of Blondel (now being printed as several installments in the FANA Journal, beginning in the Fall, 2013, issue). Thus, the references to myself as “editor”, and to the “End Note 3 under this section” which deals in much more detail with the related historical definition of “goldfish”.

my student want to know how to dying Mother of pearl to be blue color . how process and ingredient?