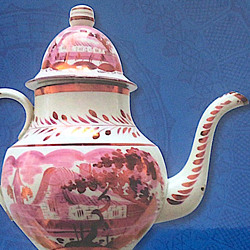

Gorham Manufacturing Company, Tureen, 1884. Gift of Mrs. Pierre Brunschwig. RISD Museum, Providence, R.I.

Right now, “tariff” is a dirty word, as American farmers, manufacturers, workers, and consumers are being asked to pay for a trade war with China—as we went to press, tariffs on goods imported from Mexico were also being threatened. But in 1842, tariffs on imported silver products, along with a slew of other goods, worked out pretty well for U.S. manufacturers of silver hollowware and flatware. The reason was the duties imposed on all those non-silver imported goods, iron foremost among them, which were paid for at customs in cold, hard, silver or gold coins. In those days, silver coins were the primary raw materials of American silver manufacturers. Thanks to the abundance of coin silver, as it is called, and the fact that foreign competition was effectively priced out of the market, the silver teaspoons, sugar bowls, and serving trays produced by companies such as Reed & Barton of Taunton, Massachusetts, and Tiffany & Co. of New York, New York, were suddenly more affordable for Americans.

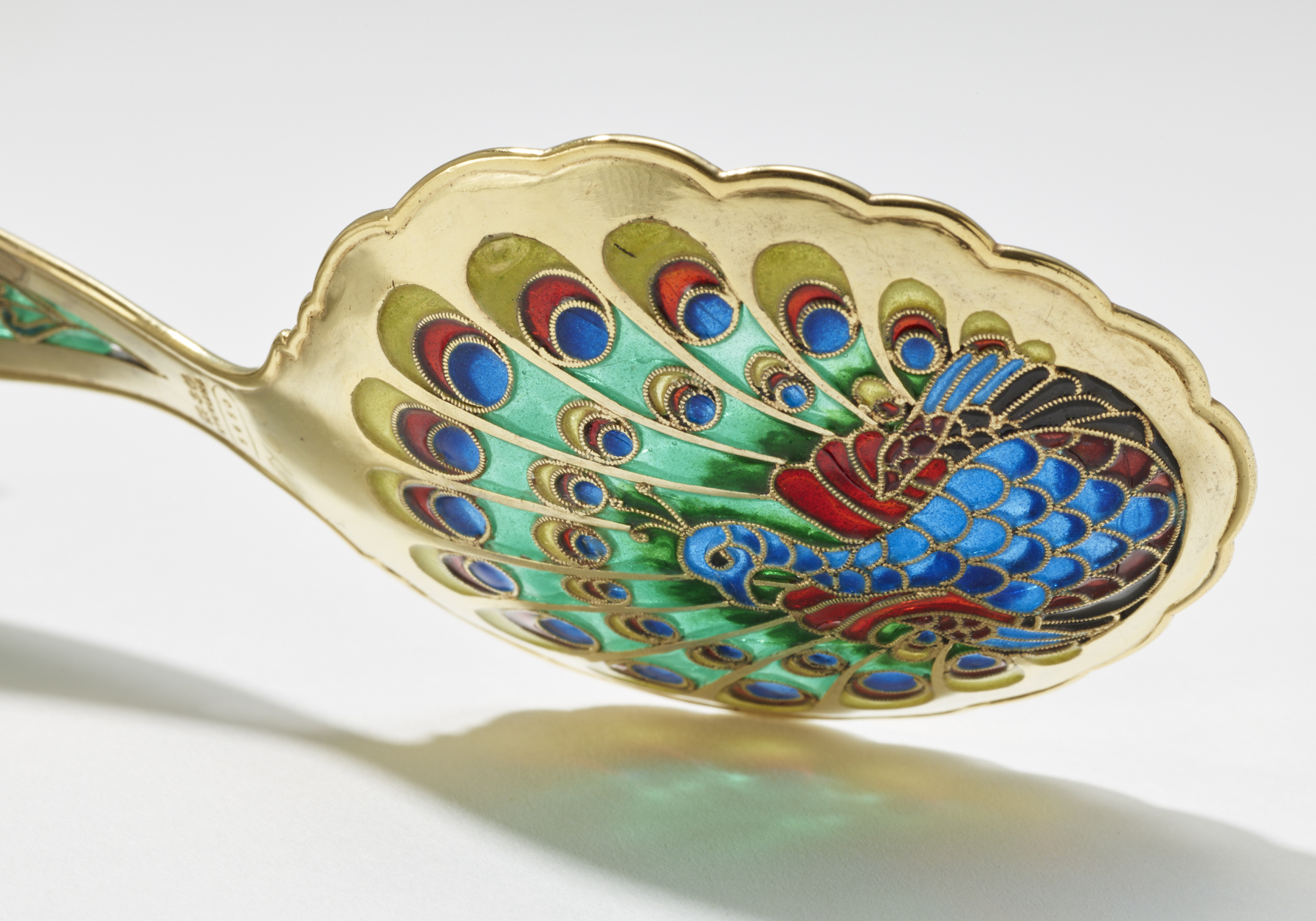

Gorham Manufacturing Company, Bonbon Spoon (detail), ca. 1893. Silver with gilding and plique-à-jour enamel. Anonymous gift. RISD Museum, Providence, R.I.

The U.S. silver manufacturer who benefited most from the tariffs of 1842 may have been the Gorham Manufacturing Company of Providence, Rhode Island. A new exhibition called “Gorham Silver: Designing Brilliance 1850-1970” explains how those tariffs helped Gorham become one of Providence’s largest employers, as well as one of the world’s premier silver manufacturers. The show, curated by Elizabeth A. Williams, who also edited a Rizzoli coffee-table tome of the same name, runs through December 1, 2019, at the Rhode Island School of Design.

Even if we weren’t looking at the events of 1842 through the prism of 2019 politics, the rise of Gorham is a peculiarly American story. Take those tariffs: 1842 was not the first time capitalism in the United States had been propped up by acts of protectionism, nor would it be the last. But as tolerant as Americans are of this form of corporate socialism, they admire disruption even more. In the case of Gorham, a key disruptive event in the company’s history occurred when John Gorham, son of the company’s founder, Jabez, boarded a paddle-wheel steamer bound for Liverpool, England, in 1852. The silver scion made the 11-day voyage in the hopes of finding some old-world technology that he could repurpose to improve the productivity of his new-world silver factory, leaving Tiffany and the rest of his competitors in the dust.

Gorham Manufacturing Company, Butter Plates (set of 24), 1879. The Gorham Collection. Gift of Textron Inc. RISD Museum, Providence, R.I.

Gorham found the technology he was looking for in Manchester, England, in a foundry run by a Scottish engineer and inventor named James Nasmyth. Ten years earlier, in 1842, Nasmyth had patented an industrial-scale steam hammer. As Gerald M. Carbone and Holly Snyder write in the Rizzoli book, “Gorham wanted Nasmyth to make a steam press that could inculcate patterns into flatware. Essentially, Gorham wanted a smaller version of the giant steam hammer; instead of hoisting a huge block of iron, it would lift the obverse half of a die containing a raised pattern above a blank of flatware resting on the sunken, or reverse, half of the die. With a stroke of the piston, the die would strike the flatware blank, inculcate [stamp] the pattern, and recoil, ready to strike again.”

“Government protection, the English steam press, and French photo paper conspired to make Gorham a great American company.”

Nasmyth could not believe that it had taken a silver manufacturer from the other side of the Atlantic to understand the potential of his invention to stamp out blanks for subsequent chasing and decoration when the English silver center of Sheffield was less than 40 miles away. “I have been trying for years,” Nasmyth reportedly told his business partner, “to get our manufacturers to adopt the steam press without success, and here comes a Yankee across the water expressly to have one built.”

Thanks to Nasmyth’s steam press, John Gorham’s company was soon producing as much flatware in a few minutes as his father’s employees had been able to produce in an entire day. John Gorham also installed a 50-horsepower steam engine in his four-story factory, which drove everything from wheels used to polish flatware to lathes used to “spin up” hollowware. Concurrently, Gorham kept track of his company’s growing line of products by employing yet another new technology, photography. The widespread acceptance in the mid-1850s of a French variation of albumen paper, which allowed photographers to make multiple prints of a single image cheaply and quickly, coincided with the growth of the company’s silver output. Not surprisingly, John Gorham built a photo studio on the top floor of his factory, so that pieces could be documented for inventory as well as marketing purposes.

Gorham Manufacturing Company, Waste Bowl (detail of chasing), 1886. Elizabeth T. and Dorothy N. Casey Fund. RISD Museum, Providence, R.I.

All of this—the government protection, the English steam press, the French photo paper—conspired to make Gorham a great American company (the historically limited roles the company doled out to its female employees, as well as its virtual ban on African American workers until the 1940s, could also be described as American traditions, if less flattering ones). Similarly, the design of mid-19th-century Gorham flatware and hollowware was inspired—or lifted wholesale, depending on your perspective—from French Rococo Revival, a style that was sweeping Europe at the time.

At first, Rococo Revival was good enough for Gorham and its customers, but in 1857, John Gorham hired George Wilkinson of Birmingham, England, as its design director, the first in a string of European-trained designers to hold that pivotal position at Gorham. Wilkinson moved the style of the company’s products backward a few hundred years from Rococo Revival to the Renaissance, while the shapes of its pieces were pushed back in time further still to the classic forms and motifs of the ancient Romans and Greeks.

Gorham Manufacturing Company, Martelé Writing Table and Chair, 1903. Gift of Mr. and Mrs. Frederick B. Thurber. RISD Museum, Providence, R.I.

By the middle of the 1870s, another non-American aesthetic would have an even more profound influence on Gorham: Japanese art, which spawned a Western tribute style known as Japonism, as well as a broader sensibility known as the Aesthetic Movement. At Gorham, Japonism manifested itself in three-dimensional birds and insects, along with two-dimensional scenes from the natural world. These elements were soldered or chased onto plates, tureens, and other examples of Gorham silver, which by now was offered in both silverplate and sterling.

Eventually, in Europe, Japonism would morph into Art Nouveau, which Gorham would import at the end of the 19th century for its wildly successful Martelé line. But before that, in the 1870s and ’80s, Japonism would lead to a uniquely Gorham aesthetic (finally!) called the Narragansett pattern. For these pieces, Gorham designers would beachcomb the coastline practically outside the doors of the ever-growing Gorham factory for seaweed, seashells, and crustaceans, which were subsequently cast into serving spoons and forks.

Gorham Manufacturing Company, Narragansett Salad Set, ca. 1885. Museum purchase: Bequest of Ida Littlefield. RISD Museum, Providence, R.I.

Because Gorham did much of the literal gilding during the Gilded Age that followed the end of the Civil War, the RISD exhibition and Rizzoli book devote a good deal of space to the insane variety of silver pieces Gorham offered customers in the second half of the 19th century. At one point, Gorham included as many as 1,000 different pieces of sterling and silverplate in its catalog, from humble crumb scrapers to elaborate epergnes.

The show and book also pay particular attention to a service commissioned by Henry and Elvira Furber, who made their fortune in the insurance industry. The commission, executed between 1866 and 1880, would eventually consist of 816 pieces—this service for 24 actually included 24 asparagus tongs—for which 20 oak cases were custom built by Gorham. Nor is the Furber commission even the most excessive example of Gorham’s output. For example, according to data culled from Gorham’s costing ledgers from the late 1880s, a single tea service might require more than 700 hours of elaborate chasing. That translates to three months worth of 60-hour weeks by a single worker, all to make the act of drinking a cup of tea more pleasant.

The Gilded Age, though, was one of economic ups and downs. For example, the Panic of 1873 forced John Gorham from his namesake company. In this light, one cannot help but wonder at the motivation behind the founding of Gorham’s Ecclesiastical division, to supply the lucrative church market, in 1885. Perhaps it was to encourage the good Lord to look more charitably on a business whose bread-and-butter was manufacturing sterling silver butter knives and gilded butter plates so that the world’s most wealthy titans of industry could better enjoy their daily bread. On the other hand, an Ecclesiastical division may have simply been good for business, which may be the most American thing about Gorham of all.

Gorham Silver: Designing Brilliance 1850-1970 is now available from Rizzoli at Amazon. If you buy something through a link in this article, Collectors Weekly may get a share of the sale. Learn more.

Copper Chronicles: How a Shipyard Worker Hammered Artillery Shells into Art

Copper Chronicles: How a Shipyard Worker Hammered Artillery Shells into Art

Saving Vermont History, One Silver Spoon At a Time

Saving Vermont History, One Silver Spoon At a Time Copper Chronicles: How a Shipyard Worker Hammered Artillery Shells into Art

Copper Chronicles: How a Shipyard Worker Hammered Artillery Shells into Art The Kalo Shop, a Mecca for Arts and Crafts Sterling Silver

The Kalo Shop, a Mecca for Arts and Crafts Sterling Silver Gorham SilverIn 1831, Jabez Gorham partnered with Henry Webster to found the silver comp…

Gorham SilverIn 1831, Jabez Gorham partnered with Henry Webster to found the silver comp… SilverHolding a piece of sterling silver flatware in the palm of the hand is like…

SilverHolding a piece of sterling silver flatware in the palm of the hand is like… Mari Tepper: Laying it on the Line

Mari Tepper: Laying it on the Line Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry

Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry How Jim Heimann Got Crazy for California Architecture

How Jim Heimann Got Crazy for California Architecture Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of

Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick?

Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick? When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll

When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll How One Artist Makes New Art From Old Coloring Books and Found Photos

How One Artist Makes New Art From Old Coloring Books and Found Photos Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures

Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History

Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Fascinating.

Wonderfully informative!

wow !!! great history on the company and the writing desk and chair stunning!!!