This 1909 iron has a handle that doubles as a liquid-fuel tank. Note how the tank attaches to the heated part of the iron via a wooden arc, no doubt to keep the handle from overheating and turning it into a small bomb.

As a professor of geology, Kevin McCartney can tell you all sorts of interesting things about iron. For example, he might point out that iron is the most abundant element on Earth, that it’s magnetic, and that when iron meets oxygen, rust happens. But if you really want to get Kevin McCartney going, ask him about irons, you know, those weighty symbols of domestic drudgery designed to press wrinkled fabric flat. “Talking about the diversity of irons is like talking about the diversity of cars,” McCartney tells me over the phone. “You’ve got your race cars, pedal cars, sports cars, vans, and let’s throw some trucks in there as well. That’s the kind of enormity you get with irons.”

“In the latter half of the 1800s, the woods were full of inventors.”

McCartney has been collecting antique sad irons (“sad” being a derivation of an Old English word for “solid”) since he was in high school; his first iron cost him a dollar. He’s got irons that spent their working days flattening shirts, irons that were designed to make weather-worn hats look as good as the day they were blocked, and a slew of irons engineered for specialty work, from polishing starched collars and cuffs to pressing fluted flourishes into the ends of starched Victorian skirts.

Kate and Kevin McCartney with small portion of Kevin’s iron collection on display at the Old Iron Inn.

“I was the first and weirdest of my family, and a collector of everything,” McCartney says, explaining his preternatural passion for this humble, household appliance. As a kid, McCartney collected a few baseball cards, though he was more interested in coins, stamps, and old radios. His main childhood collectibles were actually fossils, which was probably an early clue that he was destined for a career as a geologist and research paleontologist. “Once I became active academically,” he says, “fossils were no longer a hobby, so my collecting just sort of coalesced around irons, mostly because they were inexpensive.”

Today, the 500 or so irons and 150-some-odd iron stands, aka trivets, in McCartney’s collection are on display at the Old Iron Inn, a bed and breakfast he runs in Caribou, Maine, with his wife, Kate (“I collected the irons, she collected me”). Although he has a complement of European-made irons, the vast majority of his irons are American and date from the second half of the 19th century to the first few decades of the 20th.

This circa 1920 British gas-jet iron rests on a graniteware stand. When connected, flames shot into the iron, heating its base.

“In the latter half of the 1800s,” he says, “the woods were full of inventors. All these handymen were looking to invent something that could make them some money, so they came up with all sorts of weird irons and other gadgets. They’d go to the local foundry and convince the owner their invention was going to work. The foundry owner would say ‘Sure, let’s make ’em,’ and then maybe sell a hundred, maybe a thousand.” This phenomenon happened in town after town, which is why, today, there are so many different irons bearing the marks of so many different foundries.

For McCartney, irons are not just the story of American invention. They also illustrate how technology was used to help people stay abreast of—some might say “conform to”—the social conventions of the day. Just as a band of red in the side of a sandstone cliff might indicate the presence of iron ore, McCartney’s irons are evidence of a time when ironed clothing was a sign of social status, long before the arrival of permanent-press fabrics or—heaven forfend!—shirts designed to be worn untucked. Simply put, people spent an enormous amount of their time ironing. A typical household might have had as many as 10 different types of irons, which were heated on special laundry stoves designed to hold a ring of irons around their perimeters, along with numerous detachable bases and slugs getting hot on top.

This 1875 iron has a handle at one end so its bases could be rotated, and a tank at the other for whale oil, which was used to heat the iron.

In households heated by natural gas, graniteware cradles were manufactured to hold specially designed gas-jet irons, whose bases were heated by gas flames shooting out of the cradle and into the iron rather than by contact with a stove. Other natural-gas irons featured gas fittings that allowed the bases to be heated directly; once hot, the gas line to the iron would be disconnected and the homemaker would proceed with their ironing.

This multiplicity of irons in a household was important because so many different articles of clothing needed ironing. Although there were lots of multi-tool models on the market, most irons were designed to do only a single ironing task. So, manufacturers made irons for an incredible variety of ironing applications, which is how collectors like Kevin McCartney can quickly end up with hundreds of irons, no two exactly the same.

This late-19th-century trade card shows various types of sad irons in use and being heated. In the foreground are several fluting irons, which were heated by inserting hot rods into the device.

Another reason for multiple irons in a home, particularly those heated on stoves or by natural gas, is that all sad irons shared a major flaw—they cooled off. That’s why homemakers needed all those extra heated bases and slugs at the ready to get through a day’s ironing. In the case of stove-heated irons, that also meant they were obliged to do their ironing close to the iron’s heat source, regardless of the season, making the work of ironing all the more of a hardship.

In the days before electricity, the problem of heat loss in irons spurred invention, from hollow irons that would be filled with hot coals or charcoal, to irons whose bases were heated by liquid fuels such as kerosene or, if you were exceptionally wealthy, whale oil. In some cases, irons heated from the inside sported two ironing surfaces under the handle, so that as one surface cooled off, the user could pull a lever, rotate the surfaces, and then continue ironing with a surface that was nice and hot while the other one heated back up.

When the top of this late-1700s French iron was raised, it could be filled with hot coal to heat the iron’s base.

Irons heated by various types of fuels were ubiquitous. “I’ve seen collections of gas or fuel irons that contain 500 different designs, makes, and manufacturers, in just one person’s collection,” McCartney says. “There can easily be that many irons using a single technology from a single country in Europe; cross the border, and you’ll find another collector who has a similarly large collection of entirely different irons using that same technology. It’s amazing.”

From the vantage point of the 21st century, holding an object in one’s hand that is essentially on fire in order to flatten flammable garments sounds kind of crazy, but heat portability allowed homemakers to do their ironing away from the stove, which had to be a relief during hot summer months. In this way, technological innovation was not merely a response to the problems of heat loss or the opportunities presented by portable fuels—it addressed an essential quality-of-life issue as well.

This Swedish iron, resting on its trivet, was heated by liquid fuel and featured an exhaust port in the front.

Electric irons arrived in the 1890s. McCartney does not collect these. Again, from the perspective of the 21st century, you’d be forgiven for concluding that once electric irons arrived, it must have been game-over for coal, liquid fuel, and natural gas irons, right? In fact, initially, electric irons were perceived to be more dangerous than irons filled with billowing flames and potentially explosive fuel tanks in their handles. That’s because it wasn’t until 1928 and the invention of the thermostat that electric irons had more than one heat setting—high. As counterintuitive as it might seem today, for almost 40 years, electric irons were more deadly than ones heated with actual fire.

“Electricity was the nuclear power of its day in the sense that people were not thinking rationally about it,” McCartney says. “It was bad. People got electrocuted, and there was no temperature regulation in those irons. You’d plug it in until it got really, really hot, then you’d unplug it and do your ironing. When it cooled off, you’d plug it in again, unplug it, use it again, and so on. And if you plugged it in and the baby started crying and you got distracted and forgot to unplug it, you’d lose your house. These things were fire hazards.”

Tailor’s irons were larger than models meant for home use. This tailor’s iron was heavy to press woolens and features a large side tank designed to hold liquid fuel. The large size of the tank allowed the tailor to work for extended periods of time.

Recently, McCartney made a series of informative YouTube videos about his collection, with Kevin as the genial, predictably professorial host, and Kate behind the camera. As of this writing, 19 videos, all shot at the Old Iron Inn, have been posted, mostly on specific types of irons—coal irons, fluters, flat irons, etc. Given McCartney’s vocation, you could think of them as a solid 100-level course on sad irons, maybe a 201, but the videos also feel like chapters in a book.

“I started working on a book 10 years ago,” McCartney explains. “I realized that because there’d probably be chapters on all the categories—the hat irons, the sad-iron heaters, the sad-iron stands, and the rest—I’d probably need a better collection to draw from than I had at the time, both for the photographs I’d want and to gather better knowledge than I had. So, for the last 10 years, I’ve been rounding out the collection with an eye to a book. But these days, no one’s going to publish a book unless they know that they can sell at least 2,000 copies. Frankly, there aren’t 2,000 people in the world who are going to buy a book about antique irons.”

This hat iron from 1908 was powered by natural gas.

Maybe so, but there are definitely enough people in the world to justify a series of YouTube videos. Besides, like a lot of us, McCartney has recently had a bit of time on his hands. “The YouTube project is a product of COVID-19,” he says. “This summer, I wasn’t able to go to my office, but this was something we could do. So Kate and I decided to kick things into gear, and here we are.”

In one video, McCartney demonstrates how a fluter iron was actually used. “We’d shot two videos on fluter irons,” he tells me, “the hand fluters and the machine fluters. After they were posted, I got an email from a collector saying, ‘You know, you didn’t do a demonstration showing the process. That might have helped.’ I thought about that and realized he was right, that we really should figure out what it took to do fluting.”

The 1887 Elgin hand fluter iron was heated by inserting a hot slug between the base of the iron and its lower fluted surface.

A rival YouTube video was not particularly helpful. “They had put the whole iron, top and bottom, in the oven, using rags to keep from burning their hands. So I called some members of the Pressing Iron and Trivet Collectors of America, thinking somebody there would be able to give me advice. But they said, ‘Kevin, nobody does this. Nobody even knows anyone who’s done this in 50 years.’ The thing is, though, it’s not that hard. I mean, the instructions are written plainly on the irons: ‘HEAT THIS’ and ‘PUT THIS ON TOP OF STOVE.’ So Kate and I got some starch, and after a couple or three iterations, we figured it out. I don’t think my great, great, great, great grandmother—which is how far back I’d have to go—would have said I’d done a good job, but then again, I don’t have a great, great, great, great grandmother around to show me how.”

Machine fluters such as this Dudley from 1876 featured two heated fluting surfaces rather than just one.

The last video McCartney plans to post before the school year starts is on buying. “I’m an academic,” McCartney says, “so one of the things I like to do is get the perspectives of antiques dealers, to get their takes on things. I think it’s important to treat antiques dealers well,” he adds. “The tendency is for people to walk into an antiques shop and dicker until the price is barely above what the dealer paid for it. But the dealer behind the counter has probably worked very hard to get that thing you want. Antiques dealing is a tough business; you can’t just order items wholesale out of a catalog, you often have to chase them down, and you have to prioritize what you spend your money on. I want to have a good relationship with a dealer, so that if they see something special, they might think, ‘Kevin’s going to like that.’”

McCartney knows that he’ll never have the biggest collection of antique sad irons in the world, but that’s not his goal. “There are collections out there that have 3,000, 5,000 irons in them,” he says. “The collectors who have put those collections together buy irons like some people buy stamps. I have a pretty good collection,” he allows. “It’s not by any means the largest or best in the country, but after 50 years, it’s as good a collection as it can be.”

(To watch Kevin McCartney’s sad-iron videos, visit Kate McCartney’s YouTube page. For more information about the Old Iron Inn, visit oldironinn.com.)

The Government-Surplus Machines That Power a Cutting-Edge Science Museum

The Government-Surplus Machines That Power a Cutting-Edge Science Museum

How Gorham Wed New Technologies With Classic Craftsmanship to Gild the Gilded Age

How Gorham Wed New Technologies With Classic Craftsmanship to Gild the Gilded Age The Government-Surplus Machines That Power a Cutting-Edge Science Museum

The Government-Surplus Machines That Power a Cutting-Edge Science Museum Copper Chronicles: How a Shipyard Worker Hammered Artillery Shells into Art

Copper Chronicles: How a Shipyard Worker Hammered Artillery Shells into Art Sad and Flat IronsSad irons, also called flat irons or smoothing irons, are shaped pieces of …

Sad and Flat IronsSad irons, also called flat irons or smoothing irons, are shaped pieces of … Mari Tepper: Laying it on the Line

Mari Tepper: Laying it on the Line Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry

Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry How Jim Heimann Got Crazy for California Architecture

How Jim Heimann Got Crazy for California Architecture Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of

Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick?

Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick? When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll

When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll How One Artist Makes New Art From Old Coloring Books and Found Photos

How One Artist Makes New Art From Old Coloring Books and Found Photos Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures

Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History

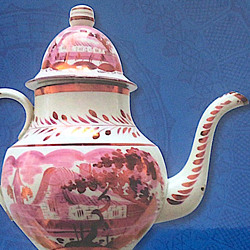

Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Kevin its a wonderful thing you and your wife are doing for the Iron Collectors, I have enjoyed viewing your videos and saved them in my archive. I too am an iron collector, but not to the extent you are, some people think I am weird for collecting irons but I love history and Irons have a story to tell, there are 3 iron collectors in my town that collect, that I know of, And I too buy on ebay, My buyer name is Jackpotts. Thank You so much for doing this for us Iron collectors I can remember my Grandmother using her Mrs Potts Iron, and asking her about the Iron shoe she would put on it when ironing her white things….

Love it.

Happened upon a 1930s porcelain industrial model. Its amazing

I have a sad iron heater with a deteriored painted name on the front. It says something like:

Fanady’s

Famdy’s

Famay’s

Pamoy’s

Do you know what manufaturer this might be…

Thanks for any advise!

-Todd

I figured it out. It says Famous…

I have a small collection of sad irons as well. Lately, I’ve been drawn to salesman samples – miniature versions of the final product that were used to solicit orders, and then the final irons would be shipped to the general store from the foundry. Much rarer than your standard piece, I have 8 different versions today, and always on the lookout for more!